Laser Technologies & Almacam unveils ReTen X, next-gen nesting software with 10x Returns

Apr 16, 2025

VMPL

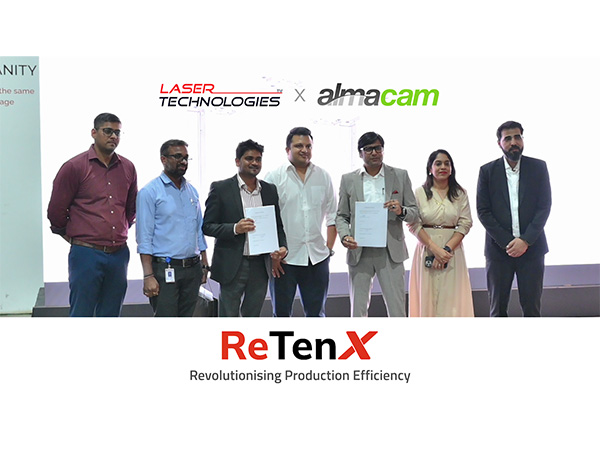

New Delhi [India], April 16: Laser Technologies, the global leader in advanced laser technology, is proud to announce the launch of ReTen X, a new nesting software developed in collaboration with AlmaCAM. This powerful tool is set to revolutionize the cutting industry by optimizing sheet metal cutting, robotic welding programming, and continuous laser cutting processes.

As a testament to its commitment to enhancing customer experience, Laser Technologies has also signed a contract with AlmaCAM, marking another significant step towards providing cutting-edge solutions to its clients.

Two pioneering customers, Himanshu Seth from Amex Engineering and Mr. Sunny Kothari from Crish Metal Works Pvt. Ltd., took the first-mover advantage by implementing ReTen X powered by AlmaCAM. Their early adoption has yielded remarkable results, with both companies achieving over 10X returns on their investment within the first year of implementation.

ReTen X boasts enhanced features that result in faster production cycles and reduced material waste. Compatible with various cutting technologies--laser, plasma, water jets, oxy-cutting, punching, and 3D tube cutting--ReTen X gives users unparalleled flexibility. The plasma and laser cutting quoting tools also provide accurate cost estimates, streamlining project planning. With an emphasis on minimizing waste, ReTen X allows industries to optimize material usage, improving both efficiency and profitability.

With over 45 years of experience, AlmaCAM is renowned for its innovation in nesting and CAD/CAM solutions. Their expertise, originally developed for textile cutting, has since expanded into robotics and 3D cutting, and their software is recognized globally for its advanced optimization capabilities.

ReTen X integrates seamlessly with ERP and MES systems, enabling real-time data sharing and fostering better communication between departments. Its cloud-based solutions offer manufacturers the flexibility to access the software remotely, while SaaS platforms ensure scalability, making it an ideal solution for dynamic production environments.

Unmatched Efficiency and Advanced Capabilities

ReTenX delivers superior nesting efficiency and is engineered to meet the demands of modern manufacturing through a host of powerful features:

Multi-Technology Compatibility: Seamlessly integrates with various cutting operations, including laser, plasma, waterjet, oxy-cutting, punching, and even 3D tube cutting.

Enhanced Quoting and Cost Estimation: Built-in tools provide precise plasma and laser cutting quotes, enabling accurate cost estimates and efficient project budgeting.

Flexible System Integration: It is designed to integrate with ERP, MES, CAD, PLM, and other enterprise systems, facilitating real-time data sharing and improved interdepartmental collaboration.

Value-Added Features: Includes comprehensive inventory management, work order control, customizable reports, and compatibility with CNC profile cutting technologies for Laser, Plasma, Oxyfuel, Waterjet, and Punching.

Pankti Agarwal, Executive Director of Laser Technologies, remarked, "We are thrilled to introduce ReTen X at our 8th Open House, where we continue to push the boundaries of innovation. Our goal is to provide our customers with cutting-edge tools that enhance their manufacturing capabilities and set them ahead in a competitive industry."

Rakesh Agarwal, Managing Director and Founder of Laser Technologies, said, "In today's fast-paced market, success comes from two key strategies: increasing productivity and minimizing scrap. ReTen X, developed in collaboration with AlmaCAM, addresses both challenges and provides manufacturers with a 10X return within the first year of implementation."

For more information, visit https://www.lasertechnologies.co.in/

(ADVERTORIAL DISCLAIMER: The above press release has been provided by VMPL. ANI will not be responsible in any way for the content of the same)